Culligan Water Systems’ Cooling Water Treatment program inhibits and prevents corrosion, scale and microbiological fouling in recirculating and closed water systems. The program minimizes makeup water and sewer costs and maximizes water use. Routine service visits by expert personnel provide detailed reports, training, and service that improve your system’s overall operation.

Culligan Water Systems can provide a wide range of chemical solutions for all aspects of cooling systems and all manners of discharge requirements:

Combined with our established, high-grade filtration systems that will improve system protection and reduce chemical consumption, our Control Equipment Solutions, and our Culligan Delivery options, Culligan Water Systems is dedicated to providing the most efficient and effective use of water, chemicals, and energy, along with maintaining maximum equipment longevity.

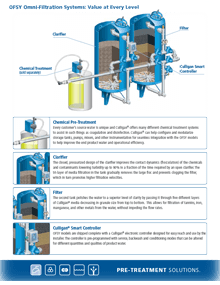

Remove suspended solids and high turbidity from your surface water supplied feed water. The OFSY model includes chemical feed, clarifier, and eight layers of filtration to capture impurities.

The E1 Reverse Osmosis System is an economical water treatment solution, which reduces operating and post treatment costs. The E1 Reverse Osmosis system helps you reduce maintenance costs by reducing contaminants* from your water that affect taste and clog equipment. Control your installation costs by using a system configured for your unique needs. Keeps your operating costs low with an easy-to-use electronic controller.

The majority of the water supplied to a cooling tower is evaporated, so why pay a sewer bill for water that does not go down the sewer? Find out if you qualify for Evaporation Credits with the help of your Culligan service representative.

Culligan® Portable Exchange Deionizers (PEDI) are a part of a multiple process treatment system that produces high-purity water required for many specialized applications. Portable Exchange Deionizers from Culligan® is a safe, convenient and economical way to obtain consistent high-purity water from potable water sources. Our reliable PEDI systems consist of activated carbon and a selection of high quality ion exchange resins in portable exchange tanks. They connect directly to your tap water supply or for polishing to RO for high-purity water production. When the PEDI tanks are exhausted, a Culligan® service technician delivers, exchanges and maintains the equipment, thus providing continuous and uninterrupted supply of high-purity water to your operation. This system reduces capital investment, on-site labor, maintenance hassles or handling of hazardous regeneration chemicals and conserves you in water and energy resources.

Deposited minerals and iron along heat exchange points can vastly increase the energy usage for a chiller and eliminate cooling efficiency in a heat exchanger. Ask your Culligan service representative about the benefits of chemical cleaning to restore efficiency and minimize future energy costs.

Internal treatment of the boiler with chemical is essential to inhibit scaling and corrosion which degrade the boilers efficiency. This can be accomplished through a diverse set of chemicals. Depending on the system’s requirements, Polymers, Tannins, and Chelates are typically utilized as internal chemical treatment solutions

The Culligan Hi-Flo 50® Filter reduces contaminants* and solids that affect equipment efficiency and water quality. Configure the system based on your requirements, adding tanks and instrumentation as your usage increases. Use the Culligan®-exclusive Smart Controller to easily manage and control your filtering options. Save time and effort with an automatic timer or sensors that reliably monitor your water usage and quality without constant supervision.

Chemical pretreatment of the feedwater typically takes place in the Feedwater Tank or Deaerator. This process is necessary to chemically remove oxygen and supplement any alkalinity required for quality boiler water. This step generally requires an oxygen scavenger and an alkalinity adjunct to ensure the feedwater is of good quality to reduce the potential for a multitude of corrosion possibilities.

Apply the correct chemical aids to neutralize charges and allow particulate to bind together with the goal of removing them from the water.

Many customers do not realize how much water is actually used in their systems, often using millions of gallons per year in their cooling process. Minimize water consumption and save on facility costs with the help of your Culligan service representative by maintaining proper conductivity setpoints and blowdown rates in cooling towers and tracking usage in closed loops.

Corrosion WILL occur in cooling towers and closed loops without chemical protection. Corrosion not only damages the equipment, it can contribute to issues with deposition and microbiological growth. Protect your equipment and your investment with a Culligan chemical program designed to provide excellent corrosion prevention, while monitoring this protection with a Culligan quarterly corrosion rate analysis.

The High Efficiency (HE) filter with patented technology delivers improved efficiency by reducing contaminants* that affect equipment performance and durability. With the Culligan® Smart Controller, available on the HE, customers can set-up a single or multiple tank system that adjusts to flow demand. Customers can also monitor their water treatment system performance, consumable usage, and maintenance needs, at a single site or across multiple ones 24 hours a day.

When you install a G1 Reverse Osmosis system, you combine cost-effective system configuration, cost-minimizing operations, and reduced post-treatment costs. The G1 Reverse Osmosis system helps you reduce maintenance costs by reducing contaminants* from your water that affect taste and clog equipment. Control your installation costs by using a system configured for your unique needs. Keep your operating costs low by monitoring and changing the G1 RO settings with an easy-to-use electronic controller. Purchasing a G1 RO is more than a sound business decision—you improve the quality of life for your building.

The High Efficiency (HE) softener with patented technology delivers improved efficiency to reduce operating costs. The HE softener reduces hard water contaminants*, reducing scale build-up that affect equipment performance. With the Culligan Smart Controller, available on the HE, the softener adjusts to influent water conditions and regenerates based on need. Customers can also monitor their water treatment system performance, consumable usage, and maintenance needs, at a single site or across multiple ones 24 hours a day.

Culligan Premier Deionizers are part of a multiple process treatment system that produces high quality water required for specialized applications. Premier deionizers use ion exchange to reduce unwanted contaminants. Choose from a flexible configuration of weak base or strong base resin tanks. You also have the option to automatically or manually control the regeneration process.

Culligan Premier Deionizers use fewer valves than competitors which helps improve reliability. A pumped regenerant system helps provide consistent regenerant usage.

When you want to produce high quality water in a demanding and variable environment, trust Culligan® filters. The Culligan Side Mount (CSM) heavyduty filter reduces contaminants* and solids that affect water quality and equipment efficiency. The Culligan®-exclusive Smart Controller makes it easy for you to set up and manage your water treatment. Using optional accessories such as an automatic timer or sensors, monitor the system and filter as needed without constant supervision, saving resources and money.

The first step, and arguably the most important step to achieving excellent results, is pretreating the make-up water to remove dissolved solids in the make-up water source by mechanical operation. Solutions typically range from utilizing Water Softening to Reverse Osmosis. The proper solution depends on the efficacy of the system and the quality of the incoming make-up water source.

Minimize by-the-pound waste removal costs by separating water out from the sludge, concentrating the wastewater solids.

Culligan® makes it simple to manage your water for drinking and industrial processes. The G2 Reverse Osmosis system is a flexible, expandable configuration customized to help meet your most demanding and exacting consumption needs. Manage the reverse osmosis system using an easy-to-reach electronic controller that automates when to get the quantity and quality of water based on your specific requirements.

Dissolved minerals naturally accumulate in cooling tower water. Deposition of these dissolved solids can occur along all points of heat exchange, greatly reducing efficiencies in chiller condensers, plate and frame heat exchangers, and air handling units. This can also lead to under-deposit corrosion and contribute to microbiological growth. Maximize your energy efficiency and prevent deposition problems with a Culligan chemical program.

The High Efficiency (HE) Twin softener with patented technology delivers improved efficiency to reduce operating costs. The HE Twin softener reduces hard water contaminants*, reducing scale build-up that affect equipment performance. The HE twin configuration consists of two independent mineral tanks, which provide a continuous flow of soft water 24 hours a day. With the Culligan® Smart Controller, available on the HE Twin, the softener adjusts to influent water conditions and regenerates based on need. Customers can also monitor their water treatment system performance, consumable usage, and maintenance needs, at a single site or across multiple ones 24 hours a day.

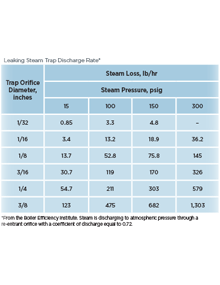

The proper type, size, and function of a system’s steam traps is imperative for proper steam utilization. Faulty steam traps waste energy which increases the operational cost of the steam system. This value-added service analyzes a plant’s steam traps to ensure their correct operation.

The Culligan® Top Mount (CTM) Series filter models use the latest control valve technology to offer superior flow rates and long-lasting performance for commercial and industrial applications. The top-mounted control minimizes the system’s footprint and is constructed of a corrosion-resistant, heavy duty plastic tested in extreme operating conditions to service all types of problem water (high chloramines, heavy iron, etc.). The CTM valve and system also carry certification for testing and passing the highest drinking water standards. The CTM includes integrated vacuum breakers and pressure relief valves to protect the system in addition to possessing an integrated flow meter for highly accurate reporting. Each CTM operates with a Culligan® Smart Controller which provides users access to the Culligan® technology platform of intercommunicating systems, remote monitoring and water and energy saving accessories.

No limits for your water quality regardless of quantity—the Culligan G3 Reverse Osmosis system processes water to help meet your most demanding and exacting industrial requirements. The durable reverse osmosis membrane processes large volumes while reducing water waste; you can manage the system using a touch panel electronic controller. Better quality water improves

industrial processes by reducing contaminants* that corrode and clog equipment, so your investment in the Culligan G3 RO benefits your operations for years to come.

Cooling towers provide an ideal environment for bacteria growth, causing health and safety concerns. Biofilms can be every bit as insulating as mineral deposition, minimizing energy efficiency, and can also lead to microbiologically induced corrosion. In a closed loop, certain corrosion prevention programs can actually feed and promote bacteria development. Minimize your risk for Legionella and other microbiological based concerns with a properly applied Culligan chemical program.

The High Efficiency (HE) Twin softener with patented technology delivers improved efficiency to reduce operating costs. The HE Twin softener reduces hard water contaminants*, reducing scale build-up that affect equipment performance. The HE twin configuration consists of two independent mineral tanks, which provide a continuous flow of soft water 24 hours a day. With the Culligan® Smart Controller, available on the HE Twin, the softener adjusts to influent water conditions and regenerates based on need. Customers can also monitor their water treatment system performance, consumable usage, and maintenance needs, at a single site or across multiple ones 24 hours a day.

To protect the system piping network and capital equipment, a steam and condensate chemical is added to buffer the pH. These chemicals are most commonly a blend of neutralizing amines and filming amines which facilitate a buffered pH (pH of 7.5-9). Buffering the pH reduces the potential for the formation of carbonic acid, which is the main contributor of a system’s deterioration.

Foaming occurs when a water system with a foaming contaminant mixes with air. Prevent foaming from occurring with Antifoam or knock it out after it happens with a Defoamer.

These value-added services ensure the utmost steam system efficiency. The resulting information can be utilized to identify capital equipment operation, cost savings opportunities, as well as facilitating the plant’s understanding of their steam system.

Steam Mechanical Troubleshooting identifies the correct operation of steam equipment.that is essential to support plant processes. Culligan can help troubleshoot the issue for solution development.

The Steam Trap Analysis determines whether the proper type, size, and function of a system’s steam traps is being applied. Faulty steam traps waste energy which increases the operational cost of the steam system.

Conducting the Annual Boiler Inspection allows Culligan to evaluate the overall operational effectiveness of the Boiler System’s Chemical Treatment Program.

The Softener Inspection can be accomplished any time of the year; however, it is best to inspect the system in conjunction with the Annual Boiler Inspection. Culligan can conduct an elution study as well as inspect the aspects of the softener for correct function.

Heavy metal removal from waste streams is an environmental necessity. Remove them chemically with the proper Culligan chemical additive or utilize Culligan’s vast knowledge of ion exchange to remove them mechanically by capturing the metal ions in resin tanks.

The Culligan® Top Mount (CTM) Series softener models use the latest control valve technology to offer superior flow rates and long-lasting performance for commercial and industrial applications. The top-mounted control minimizes the system’s footprint and is constructed of a corrosion-resistant, heavy duty plastic tested in extreme operating conditions to service all types of problem water (high chloramines, heavy iron, etc.). The CTM valve and system also carry certification for testing and passing the highest drinking water standards. The CTM includes integrated vacuum breakers and pressure relief valves to protect the system in addition to possessing an integrated flow meter for highly accurate reporting. Each CTM operates with a Culligan® Smart Controller which provides users access to the Culligan® technology platform of intercommunicating systems, remote monitoring and water and energy saving accessories.

Utilize Culligan’s chemical water treatment programs to prevent corrosion, deposition, and microbiological growth in your Cooling and Heating Systems. Protect your cooling towers and chillers, steam boilers and steam lines, closed loops and equipment, all while minimizing water and energy consumption, facilities costs, and downtime.